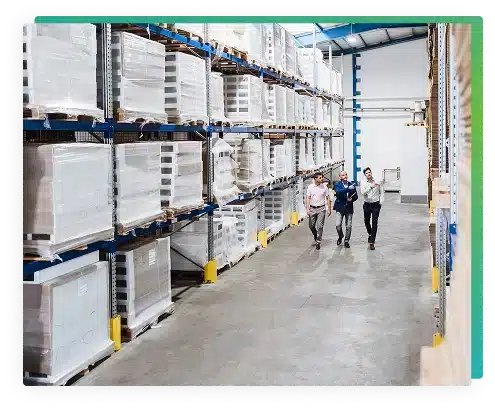

Warehouse cleaning is about more than sweeping floors. It’s about protecting worker safety, keeping equipment in top condition, and meeting compliance standards that keep your operations running.

CleanCraft designs cleaning programs for manufacturing plants, logistics centers, and corporate storage facilities. With 30-plus years in business and a local workforce of 400-plus, we deliver consistent results, clear communication, and convenient work order management through our CleanCraft Connect portal, which our recurring clients use to submit requests.

Ready to see a tailored plan for your facility?

What Warehouses Need From a Cleaning Partner

High traffic from forklifts and foot traffic, constant inventory movement, and large open spaces make warehouses complex to maintain. Dust buildup, spills, and debris can quickly impact safety, product quality, and operational efficiency.

Common issues we solve include inconsistent vendor quality, lack of high-dusting capability, and slow response times for urgent issues. CleanCraft addresses these with facility-specific scopes, trained industrial crews, and real-time reporting.

Our Approach to Warehouse Cleaning

Customized Scopes and Schedules

We build site-specific task lists for high-traffic aisles, loading docks, mezzanines, storage racks, and equipment areas. Daily tasks target debris removal, spills, and high-touch surfaces. Weekly and monthly cycles handle periodic needs such as high-dust vacuuming, machine scrubbing, and safety line maintenance.

Trained, Vetted Industrial Teams

Every technician is OSHA-compliant and trained in safe chemical handling, equipment operation, and secure access procedures. We coordinate with your safety and operations teams to ensure our crews work safely around active machinery and inventory. Consistent staffing means the same team members learn the workflow and traffic patterns of your facility.

Quality Assurance You Can See

Supervisors conduct scheduled inspections, with results documented in CleanCraft Connect and backed by time-stamped photos. You can review inspection scores, request additional tasks, and track completion in one place, reducing downtime and eliminating back-and-forth emails.

Compliance and Safety First

We follow OSHA guidelines for worker safety and EPA guidance for approved cleaning products. Documentation is available for safety audits and compliance reviews, helping you maintain a safe work environment.

Operational Schedule Alignment

We plan cleaning scopes around your operational schedule, off-peak hours, overnight work, and scheduled shutdowns. Flexible coverage is available for seasonal surges, inventory counts, and special projects.

Related Industrial Services

- Manufacturing Plant Cleaning: tailored programs for production environments.

Additional Services and Industry Context

CleanCraft offers a full suite of services for facilities that demand high performance and total peace of mind.

Commercial Janitorial Services

Customized cleaning plans tailored to your building and schedule.

Office Cleaning

Polished spaces that impress visitors and energize your team.

Medical Facility Cleaning

Specialized teams trained for surgical centers, labs & hospitals.

Industrial Cleaning

Heavy-duty services for manufacturing, logistics & clean rooms.

Assisted Living Cleaning

Sensitive cleaning designed for vulnerable populations.

Infectious Disease Response & Deep Disinfection

Rapid response when health and safety are on the line.

What Our Clients Are Saying

Getting Started Is Simple

Contact Us

Frequently Asked Questions

Can you work after operational hours?

Absolutely. We schedule around your shifts, including overnight and weekends, to avoid downtime.

Do you provide high dusting for warehouse racks and beams?

Yes. Our crews are trained and equipped for elevated dust removal.

How quickly can you start service?

We can onboard new accounts quickly, often within days after the walkthrough.

Can you handle special cleaning projects during shutdowns?

Yes. We coordinate with your operations team to plan and execute intensive cleanings during non-production periods.